Methyl Fluorosilicone Oil

Fluorosilicone oil TPD-FS8012 is methyl terminated low molecular weight polymer. Since the introduction of trifluoropropyl on silicon atoms, it has excellent oil & solvent resistance, good lubricity, low surface tension and low refractive index, while remains wide working temperature range of silicone oil(-40~204℃).

Product Introduction

Fluorosilicone oil TPD-FS8012 is methyl terminated low molecular weight polymer. Since the introduction of trifluoropropyl on silicon atoms, it has excellent oil & solvent resistance, good lubricity, low surface tension and low refractive index, while remains wide working temperature range of silicone oil(-40~204℃).

Benefits of Methyl Fluorosilicone Oil

Low-Temperature Flexibility

Methyl Fluorosilicone oils remain flexible even at low temperatures, making them ideal for use in cold climates or refrigeration systems.

Excellent Sealant Properties

These oils have excellent sealing properties, making them perfect for use in gaskets, O-rings, and other sealing applications where a tight seal is essential.

Chemical Resistance

Methyl Fluorosilicone oils are highly resistant to a wide range of chemicals, including acids, bases, and solvents. This makes them ideal for use in applications where exposure to harsh chemicals is common.

Temperature Stability

These oils can withstand extreme temperatures, from as low as -70°C to as high as 230°C. This high temperature stability makes them suitable for use in demanding applications where other materials may fail.

Compatibility with Other Materials

Methyl Fluorosilicone oils are compatible with a wide range of materials, including metals, plastics, and elastomers. This makes them versatile and easy to integrate into existing systems.

Hydroxy fluorosilicone oil is a colorless, odorless or light yellow transparent liquid, suitable as a structure control agent in the processing of fluorosilicone rubber, which can effectively prevent the structural phenomenon of fluorosilicone rubber.

Vinyl fluorosilicone oil is polymerized from fluorosilane monomers, with hydroxyl groups at both ends of the molecule. Methyl or vinyl silicone modified materials.

Medical fluorosilicone oil is a kind of transparent fluorosilicone oil polymerized with dimethylsiloxane and trifluoropropylmethylsiloxane.

Why Choose Us

World-wide expertise

We know international markets and trends. Our expertise, experience and network cover all corners of the world.

Competitive prices

We offer our products at competitive prices, making them affordable for our customers. We believe that high-quality products should not come at a premium, and we strive to make our products accessible to all.

Rich experience

Has a long-standing reputation in the industry, which makes it stand out from its competitors. With over many years of experience, they have developed the skills necessary to meet their clients' needs.

High quality products

We always put customer needs and expectations in the first place, refine on, continuous improvement, to seek every opportunity to do better, to provide customers with their expectations of quality products, to provide customers with the most satisfactory service at anytime.

Customer satisfaction

We are delivering high quality services that exceed our clients' expectations. We strive to ensure that our clients are satisfied with our services and work closely with them to ensure their needs are met.

Efficient and convenient

The company has established marketing networks around the world to provide high-quality services to customers in an efficient and convenient manner.

Methyl-fluorosilicone oil, a specialized variant of silicone oil, is a synthetic fluid characterized by its unique combination of methyl and fluorine substituents on the siloxane backbone. This chemical composition imparts exceptional thermal and chemical resistance, making it an ideal choice for various industrial applications. The primary function of methyl-fluorosilicone oil lies in its use as a high-performance lubricant and sealant, particularly in environments where traditional lubricants may fail. This versatile fluid's molecular structure ensures stability under extreme temperatures and aggressive chemical conditions, rendering it indispensable in aerospace, automotive, and electronics industries. As a result, the Methyl-fluorosilicone oil market is defined by the demand for this advanced silicone oil variant that provides superior lubrication, insulation, and resistance to harsh environmental factors.

Opportunities within the Methyl-fluorosilicone oil market are multifaceted, driven by its unique properties and the growing need for specialized solutions in various sectors. The expanding aerospace sector, with its stringent performance requirements, presents a significant opportunity for Methyl-fluorosilicone oil as a lubricant and sealant in critical components. Additionally, the increasing demand for high-performance elastomers and sealants in automotive applications further propels the market. Segmentation of the market is based on end-use industries such as aerospace, automotive, electronics, and others. Each segment exhibits distinct requirements and specifications, driving the need for tailored formulations of Methyl-fluorosilicone oil to meet industry-specific challenges. This segmentation not only reflects the diverse applications of the product but also underscores its adaptability and relevance across a spectrum of technologically advanced sectors.

Fluorosilicone Oil Technical Index

|

Item |

Unit |

TPD-FS8012-300 |

TPD-FS8012-500 |

TPD-FS8012-1000 |

TPD-FS8012-10000 |

|

Appearance |

Colorless transparent or light yellow transparent liquid |

||||

|

Viscosity at 25℃ |

mm2/s |

300 |

500 |

1,000 |

10,000 |

|

Viscosity at -18℃ |

mm2/s |

5,200 |

12,000 |

20,000 |

420,000 |

|

Viscosity at 100℃ |

mm2/s |

27 |

36 |

69 |

670 |

|

Viscosity at 204℃ |

mm2/s |

5.3 |

6.4 |

10.3 |

75 |

|

Flashing Point |

℃ |

≥260 |

≥270 |

≥300 |

≥310 |

|

Freezing Point |

℃ |

≤-47 |

≤-40 |

≤-31 |

≤-31 |

|

Working Temperature |

℃ |

-40~204 |

|||

|

Volatility (200℃/4hr) |

% |

<5 |

|||

What Are the Applications of Methyl Fluorosilicone Oil

Lubricant

Fluorosilicone oil has good lubricity under extreme pressure conditions and can be used as a lubricant for various mechanical parts, such as bearings, gears, sealing gaskets, etc. In particular, the lubrication performance of fluorosilicone oil is particularly outstanding for high-speed bearings in the presence of chemical media.

In the watch industry and micro-mechanical industry, fluorosilicone oil can reduce the surface friction coefficient due to its low surface energy characteristics and is used as a high-grade lubricant.

Fluorosilicone oil can also be used to prepare fluorosilicone grease and fluorosilicone paste. These products have a wider operating temperature range and better lubrication performance. They are suitable for the lubrication of high-speed and heavy-load bearings in contact with chemical reagents, as well as the lubrication and sealing of valves in contact with corrosive compounds.

Defoamer

Fluorosilicone oil is very effective in reducing the surface tension of various foaming systems due to its low surface tension characteristics, so it is often used as a defoamer. It can be used in the fields of petroleum, textile, synthetic rubber and resin industries, coatings and ink industries, food processing and fermentation industries, and medical applications.

Surface treatment agent

Fluorosilicone oil can form a molecular assembly film with an outer chemical composition of -CF3 and high hydrophobicity and oleophobicity on the surface of the substrate through chemical adsorption, which can greatly reduce the friction coefficient of the substrate and make it have good wear resistance under low load. Therefore, it is often used as a surface treatment agent, such as waterproof and anti-fouling finishing agent for fabrics and leather, and waterproof and oil-proof treatment of metal, glass, ceramic and other surfaces.

Release agent

Fluorosilicone oil has good anti-stickiness and lubricity, does not corrode molds, is non-toxic and safe, so it can be used as a release agent. In molding, casting, encapsulation and coating processes, fluorosilicone oil release agent can significantly improve production efficiency and product quality.

Methyl fluorosilicone oil is a linear polysiloxane with methyl end-capping and fluorine-containing groups introduced into the side chain. It belongs to modified silicone oil. Due to the introduction of trifluoropropyl on the silicon atom, methyl fluorosilicone oil has the common characteristics of siloxane and fluorocarbon compounds, and has excellent properties such as low surface tension, weather resistance, oil resistance, solvent resistance, high and low temperature resistance (-60~200℃), lubricity and chemical stability. Methyl fluorosilicone oil can be used as a defoamer, lubricant, mold release agent, and fabric finishing agent and is widely used in cosmetics, leather, aerospace, automobiles, textiles and other fields.

Hydrosilylation is a common method for preparing fluorosilicone oil. It is carried out by using the Si~H bond and C=C bond of hydrogenated silicone oil to undergo addition reaction in the presence of a catalyst. However, in order to make hydrogenated silicone oil and fluorinated compounds fully contact, a large amount of toxic and harmful organic solutions such as tetrahydrofuran, toluene, dioxane or isooctane are required as solvents. After the reaction, the solution needs to be separated. Not only is the reaction process complicated and energy-consuming, but some toxic and harmful solvents will also remain in the product.

Functional Difference Between Ethyl Silicone Oil and Methyl Fluorosilicone Oil

Basic Definitions and Classification

Ethyl Silicone Oil: Ethyl silicone oil is a type of silicone oil that remains liquid at room temperature, belonging to the class of linear polysiloxanes. It is an organosilicon product with a wide range of applications. Ethyl silicone oil is primarily classified based on the different substituent groups attached to the polysiloxane chain, where it stands out due to its specific chemical structure and properties.

Fluorinated Silicone Oil: Fluorinated silicone oil is another important class of silicone oil characterized by the presence of fluorine atoms in its molecules. This structure endows fluorinated silicone oil with unique properties such as exceptional weather resistance, lubricity, and oleophobicity. Due to these properties, fluorinated silicone oil finds applications in multiple fields.

Chemical Structure and Properties

Ethyl Silicone Oil: The chemical structure of ethyl silicone oil features alternating silicon and oxygen atoms forming the backbone, with ethyl groups and other substituents attached to the silicon atoms. This structure imparts ethyl silicone oil with excellent lubricating and dielectric properties, low volatility, low surface tension, non-toxicity, non-corrosiveness, and resistance to aging.

Fluorinated Silicone Oil: Fluorinated silicone oil combines the advantages of siloxanes and fluorocarbons in its chemical structure. The incorporation of fluorine atoms results in superior thermal stability, chemical stability, and weather resistance. Additionally, fluorinated silicone oil exhibits excellent lubricity, oleophobicity, and chemical resistance.

Areas of Application

Ethyl Silicone Oil: Ethyl silicone oil is widely used as a release agent for various rubbers and plastics due to its superior lubricating and dielectric properties. It is also employed as an insulating material in the electrical industry, precision instrument oil, hydraulic oil, and special lubricants. Ethyl silicone oil can be formulated into different viscosities to meet the needs of various fields.

Fluorinated Silicone Oil: Fluorinated silicone oil finds diverse applications due to its unique properties. In friction fields such as aerospace, automotive, machinery, and electromechanical engineering, fluorinated silicone oil demonstrates exceptional lubricity and weather resistance. Furthermore, it is used as a raw material in cosmetics, as a leveling agent in coatings, a defoamer, and as a spreading agent in pesticides.

Other Differences

Temperature Performance: Ethyl silicone oil has a wide operating temperature range of typically -60°C to 150°C, with a low temperature-viscosity coefficient. Fluorinated silicone oil, on the other hand, exhibits even higher thermal decomposition temperatures and chemical stability, maintaining stable performance under harsher environmental conditions.

Methyl Fluorosilicone Oil Performance Optimisation

Several factors must be considered to optimise fluorosilicone oil performance, especially for chemical-resistant applications.Selecting the proper fluorosilicone oil viscosity is crucial. Viscosity affects lubricant film strength and capacity to protect movingparts in harsh situations. Higher-viscosity fluorosilicone oils may protect high· performance applications, while lower-viscositylubricants may be preferable for fluid flow and low-temperature performance.

Fluorosilicone oil must be compatible with the components it will touch. Certain polymers and rubbers may swell ordisintegrate when exposed to fluorosilicone lubricants. Compatibility tests before full-scale application can prevent equipmentfailure and extend lubricant and component life.

Monitoring and maintaining the lubricant's state improves chemical resistance. Continuous exposure to harsh chemicals, hightemperatures, and mechanical stress can deteriorate even the most chemically resistant lubricants. A frequent check- up and replacement strategy based on operational environment and manufacturer guidelines can help maintain fluorosilicone oil integrity.

A complete maintenance strategy that includes cleanliness and pollution control can improve industrial operations by includingfluorosilicone oil. To maximise the oil's effectiveness and the system's dependability, it is important to keep the systems that usefluorosilicone oil clean of dust, water, and other impurities.

Our Factory

Founded in 2015, Aluda is located in Fuzhou High-tech Zone, mainly engaged in the research and development, production and sales of Fluorosilicone Rubber, Fluororubber and Hydrogenated Nitrile and other special rubbers. The company has introduced excellent technical and management personnel in the rubber and plastic industry, and has 29 technical patents for Fluorosilicone rubber.

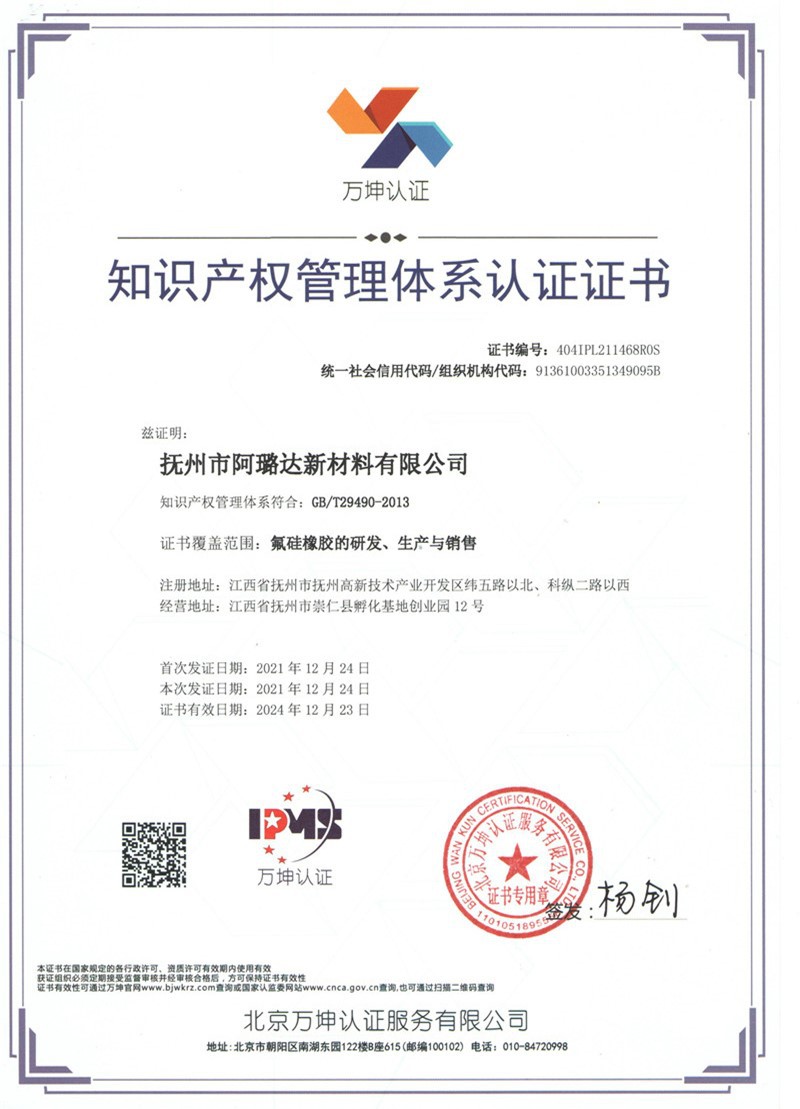

Certifications

FAQ

Q: What is fluorosilicone oil?

Q: What is methyl hydrogen silicone fluid used for?

Q: Is fluorosilicone oil resistant?

Q: Definition and Use of Methyl Fluorosilicone Oil and Hydroxy Fluorosilicone Oil

Methyl Fluorosilicone Oil is a colorless, transparent liquid with extremely low surface tension. It is widely used in cosmetics, printing, electronics, leather, textiles, lubricants and other industries. Methyl Fluorosilicone Oil is also widely used in medical and pharmaceutical fields, such as oral care, digestive system medication, artificial joint lubricants, etc.

Hydroxy Fluorosilicone Oil is an organosilicon polymer compound composed of fluorosilicate and hydroxyl groups. It has excellent permeability and water resistance, and is widely used in waterproof materials, protective coatings, humidifiers and other fields.

Q: Is Methyl Fluorosilicone Oil safe to use?

Q: How should Methyl Fluorosilicone Oil be stored?

Q: Can Methyl Fluorosilicone Oil be used in food applications?

Q: Is Methyl Fluorosilicone Oil biodegradable?

Q: Does Methyl Fluorosilicone Oil have any health effects?

Q: How does Methyl Fluorosilicone Oil compare to other oils?

Q: Is there a difference between Methyl Fluorosilicone Oil and other types of silicone oils?

Q: Differences between methyl fluorosilicone oil and hydroxy fluorosilicone oil?

Different uses: methyl fluorosilicone oil is widely used in cosmetics, medical and other fields; while hydroxy fluorosilicone oil is mainly used in waterproof materials, protective coatings and other fields.

Different properties: methyl fluorosilicone oil has lower surface tension, and its heat resistance and chemical corrosion resistance are stronger; while hydroxy fluorosilicone oil has better permeability and waterproofness.

Q: What are the key drivers for the growth of the Methyl-fluorosilicone Oil market?

Q: What are the major challenges for the Methyl-fluorosilicone Oil market?

Q: What is the chemical structure of Methyl Fluorosilicone Oil?

Q: What are the physical properties of Methyl Fluorosilicone Oil?

Q: What are the chemical properties of Methyl Fluorosilicone Oil?

Q: Can Methyl Fluorosilicone Oil be used as a lubricant?

Q: Is Methyl Fluorosilicone Oil safe for use in cosmetics?

Q: What is the shelf life of Methyl Fluorosilicone Oil?

Hot Tags: methyl fluorosilicone oil, China methyl fluorosilicone oil manufacturers, suppliers, factory

You Might Also Like

Send Inquiry